PRECISION POWDER COATING FOR LASTING PERFORMANCE Our in-house powder coating system is built for precision, consistency, and long-term durability -making it ideal for large-scale architectural and engineering projects where appearance and performance matter. How it Works:

1. Surface Preparation Each component passes through a three-stage wash system that removes contaminants and chemically treats the surface for optimal coating adhesion. A reverse-osmosis final rinse ensures a pristine, residue-free substrate.

2. Controlled Drying A 3-million BTU drying oven eliminates all moisture, creating the perfect base for flawless coating application.

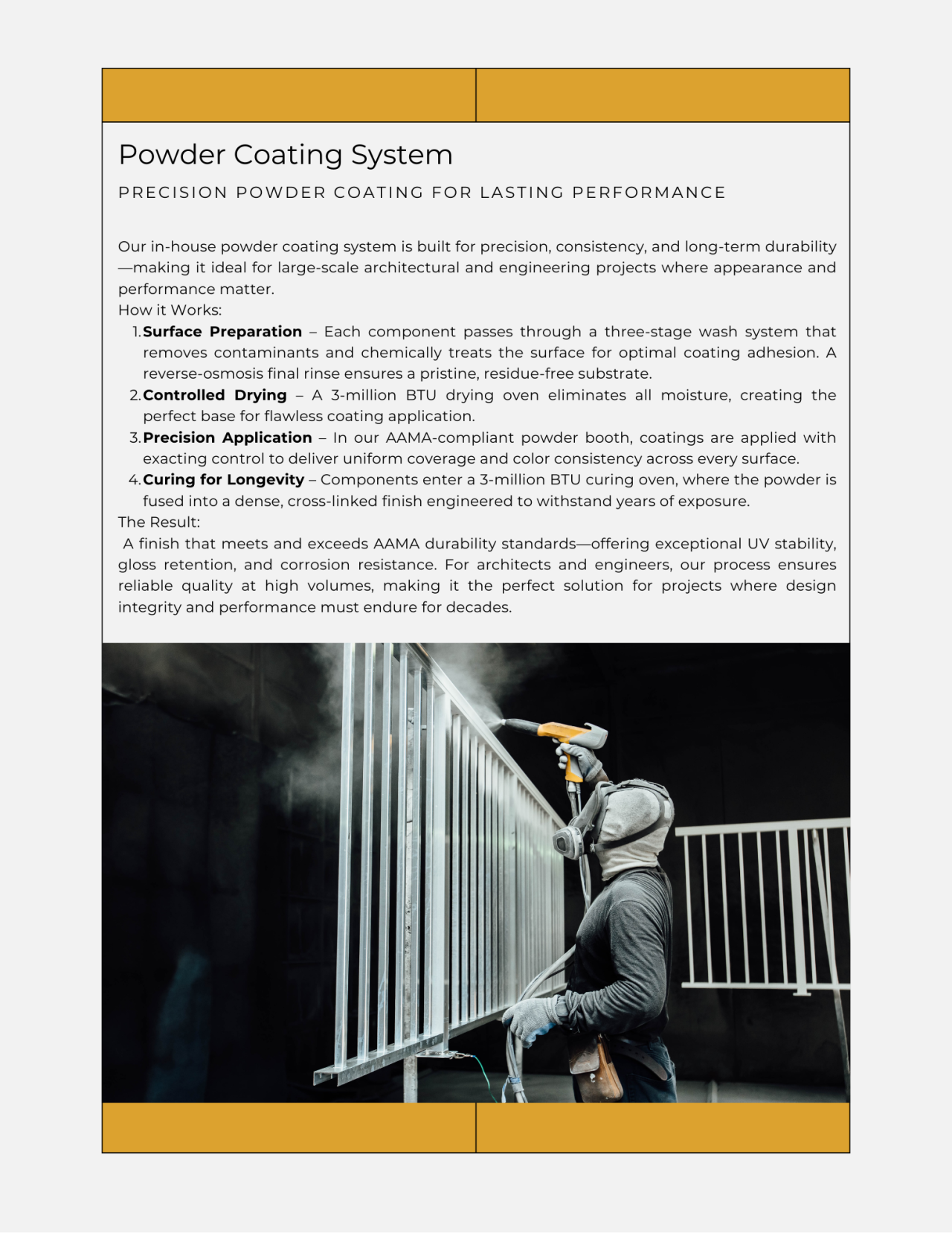

3. Precision Application In our AAMA-compliant powder booth, coatings are applied with exacting control to deliver uniform coverage and color consistency across every surface.

4. Curing for Longevity – Components enter a 3-million BTU curing oven, where the powder is fused into a dense, cross-linked finish engineered to withstand years of exposure. The Result: A finish that meets and exceeds AAMA durability standards-offering exceptional UV stability, gloss retention, and corrosion resistance. For architects and engineers, our process ensures reliable quality at high volumes, making it the perfect solution for projects where design integrity and performance must endure for decades.